Jewelry Creation

The creation of each piece of jewelry begins with an idea that eventually takes shape.

Sometimes it's simple: clients send photos or their own sketches of what they'd like to receive. Other times it's much more complex: the idea is in the air, but there's no concrete vision. In this case, a designer gets involved. The designer first creates several sketches, and only after all details are approved does the final design of the future jewelry piece emerge.

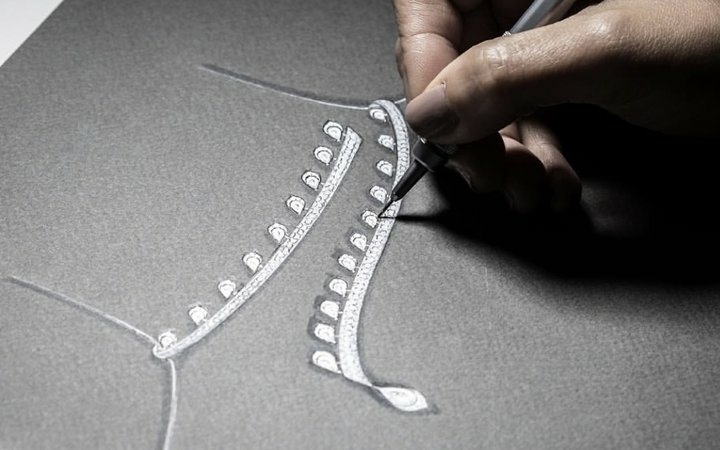

Jewelry Design Sketch

JEWELRY DESIGN SKETCH is the first stage of our work. Hand-drawn by the designer, the sketch reflects all the features and distinctive characteristics of the jewelry piece. At this stage, the dimensions of the item and other parameters are determined: which metal will be used, presence of stones and other inserts.

Based on the design, we decide on the best technical production method: 3D modeling or completely manual work (creating a wax model of the jewelry by hand).

More details about these two processes:

3D MODEL of the jewelry is created in specialized computer software by a jewelry designer. The client can view the design from all angles, and after approving all details, a 3D printer or milling machine "grows" the model of the future jewelry piece in wax.

Examples of sketches for wax models

We prefer 3D modeling for classic jewelry pieces. However, when (to put it simply) the item features three-dimensional organic forms (for example, if you want a ring shaped like a dog or wedding rings with mountain relief), we turn to JEWELRY WAX. The craftsman manually carves the future jewelry piece from wax.

Examples of 3D models

Nevertheless, nearly every piece can be created either manually or using 3D technology. It's always just a matter of choosing the optimal method!

After creating the wax model comes the next stage - CASTING in a hot furnace. :) To produce metal items, we assemble a so-called "tree" - a special structure made of wax models.

Creating the wax tree is crucial because it's used to cast all jewelry units in silver or gold. The tree consists of a central column and branches holding the wax models. Metal will flow through the branches and column, transforming the wax tree into silver or gold.

The next stage is ASSEMBLY AND FINISHING. After casting, all parts of the future jewelry piece are assembled together and the surfaces undergo external finishing. After this, the item is sent to the State Assay Inspection where it's checked for compliance with the declared standard and receives an official hallmark.

The final stage is STONE SETTING in the jewelry and FINAL FINISHING, where the piece is polished to a mirror shine. Various matte finishes and coatings may also be applied, such as rhodium plating. This is how we get the finished product.

Jewelry making is a true art form, and you can become part of it with us by designing your unique piece. We'll help bring your imagination to life!

Support it with a like!

Read also

HOW TO CARE FOR YOUR JEWELRY

Stones by Zodiac Sign

What should be an Engagement Ring

© The material is subject to the copyright of WHITELAKE. Copying, distribution or any other use of information and objects of this material without the prior consent of the copyright holder is prohibited.